Microbial Fuel Cells (MFCs) are a promising technology for treating wastewater and producing sustainable energy. The ability of bacteria to move electrons during their metabolic processes is a fascinating biological phenomenon that underpins their operations. In order to fully realize the promise of bacterial electron transport systems (ETS) in renewable energy applications, this paper examines innovative methods for utilizing them for improved MFC efficiency.

Understanding Bacterial Electron Transport Systems in MFCs

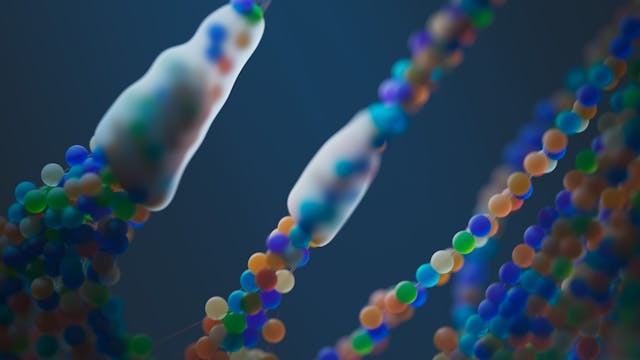

The passage of electrons during cellular respiration is facilitated by the electron transport system in bacteria, which is a chain of proteins and chemicals embedded in the cell membrane. These electrons can be transferred to an external electrode in MFCs by certain bacteria, known as electroactive bacteria, producing electricity.

Key players in bacterial ETS include:

- Outer Membrane Proteins (OMPs): These facilitate direct electron transfer (DET) to electrodes.

- Redox Mediators: These molecules, either naturally produced or externally supplied, shuttle electrons between the bacteria and the electrode.

- Conductive Pili (Nanowires): Some bacteria, like Geobacter sulfurreducens, produce conductive pili to establish physical connections with electrodes.

Understanding and optimizing these mechanisms is crucial for enhancing MFC performance.

Challenges in Utilizing Bacterial ETS for MFCs

Despite significant advances, several challenges hinder the widespread adoption of MFCs:

Due to its potential for producing sustainable energy, the use of bacterial electron transport systems (ETS) in microbial fuel cells (MFCs) has attracted a lot of interest. To improve this technology’s effectiveness and scalability, a number of issues must be resolved. We examine the main challenges of using bacterial ETS for MFCs below.

1. Complexity of Electron Transport Mechanisms

A number of intricate metabolic mechanisms that differ greatly between species are involved in bacterial ETS. The selection and optimization of bacterial strains are made more difficult by the variety of electron transfer processes, including mediated electron transfer (MET) and direct electron transfer (DET). It is still difficult to identify bacteria with effective electron transfer capabilities, such Shewanella and Geobacter, because of their unique growth needs and inconsistent performance in different environments.

2. Low Power Density

The low power production of MFCs in comparison to traditional energy sources is one of their main drawbacks. Ineffective electron transport between the bacteria and the anode is one of the causes of this problem. The MFC system’s internal resistance, biofilm thickness, and restricted surface area for bacterial colonization all prevent the best possible electron flow. To overcome this obstacle, improving electrode materials and creating biocompatible surfaces are essential.

3. Biofilm Formation and Maintenance

The development and maintenance of biofilms on the electrode surface have a significant impact on the effectiveness of bacterial ETS in MFCs. However, bacterial community interactions, nutrition availability, and environmental factors all have an impact on the dynamic process of biofilm creation. Overgrowth of biofilms that is not regulated can cause blockage, decreased electron transfer efficiency, and ultimately system failure. An ongoing technical challenge is maintaining a balanced and fruitful biofilm.

4. Environmental Sensitivity

Environmental elements like pH, temperature, oxygen concentration, and substrate concentration have a significant impact on the bacteria that are involved in ETS. Variations in these parameters can cause irregular MFC performance by interfering with bacterial metabolism and electron transfer. These problems might be lessened by creating resilient bacterial strains or genetically modifying microorganisms to resist harsh environments.

5. Electrode Material Limitations

The way bacteria and the MFC system interact is greatly influenced by the electrode material selection. Conventional materials with limited conductivity and compatible with bacterial ETS include graphite and carbon. Although they show promise, advanced materials like metal oxides and graphene-based composites are still expensive and difficult to scale for commercial use.

6. Scalability and Cost-Effectiveness

Addressing several barriers, such as material pricing, system design, and operating efficiency, is necessary to scale up MFCs for real-world applications. To assure economical energy generation, bacterial ETS integration into large-scale MFCs necessitates advancements in reactor design, electrode fabrication, and system optimization.

7. Contamination and Competition

The presence of non-target microorganisms can disrupt the desired bacterial ETS in natural or semi-controlled settings. The breakdown of vital biofilms or a decrease in the effectiveness of electron transport might result from contamination by rival microorganisms. Maintaining MFC function requires the application of efficient microbial management techniques.

Another Must-Read: Revolutionizing Wastewater Treatment: Top 5 Key Insights on Microbial Fuel Cells Advancement

Innovative Methods to Enhance Bacterial ETS Utilization

1. Genetic Engineering of Electroactive Bacteria

Genetic engineering has opened new frontiers in improving the electron transfer capabilities of bacteria:

- Overexpression of Electron Transfer Proteins: Genes encoding OMPs like OmcA and MtrC can be overexpressed to enhance DET efficiency.

- Synthetic Pathways: Introducing synthetic redox-active pathways allows bacteria to expand their electron transfer capabilities.

- Enhanced Biofilm Formation: Genetic modifications can promote biofilm stability and conductivity, optimizing electron flow.

For instance, researchers have engineered Shewanella oneidensis to produce more nanowires, significantly boosting MFC performance.

2. Integration of Nanomaterials

Nanotechnology offers a suite of tools to improve the interface between bacteria and electrodes:

- Carbon-Based Nanomaterials: Graphene, carbon nanotubes (CNTs), and carbon nanofibers enhance electrode conductivity and provide a large surface area for bacterial adhesion.

- Metallic Nanoparticles: Silver, gold, and platinum nanoparticles can serve as electron conduits, reducing resistance at the bacteria-electrode interface.

- Hybrid Nanocomposites: Combining nanomaterials with polymers or bio-compatible coatings optimizes both conductivity and bacterial viability.

Studies have shown that CNT-coated electrodes can improve power densities by up to 300% compared to traditional materials.

3. Utilization of Synthetic Mediators

While some bacteria produce natural mediators, their efficiency can be limited. Synthetic redox mediators, such as ferrocenes or quinones, are designed to:

- Increase electron shuttling efficiency.

- Reduce energy losses associated with natural mediator production.

- Operate across broader environmental conditions.

Coupling synthetic mediators with electrode modifications further enhances their effectiveness.

4. Advanced Electrode Design

The choice of electrode material and structure is pivotal for MFC efficiency. Innovations in electrode design include:

- 3D Electrodes: Porous and 3D-structured electrodes increase the surface area available for bacterial attachment.

- Conductive Polymers: Materials like polyaniline and polypyrrole offer excellent conductivity and flexibility.

- Surface Functionalization: Modifying electrode surfaces with bio-compatible coatings or chemical groups promotes bacterial adhesion and electron transfer.

For example, biofunctionalized graphene electrodes have demonstrated significant improvements in current generation.

5. Optimization of Operating Conditions

Fine-tuning the operational environment can significantly impact bacterial performance in MFCs:

- pH and Temperature: Maintaining optimal conditions enhances bacterial metabolism and ETS activity.

- Substrate Availability: Providing suitable organic substrates ensures continuous electron flow.

- Dynamic Control of Biofilm Growth: Advanced monitoring and control systems can regulate biofilm thickness to prevent overgrowth and associated inefficiencies.

6. Microbial Consortia Engineering

In natural environments, bacteria often function as part of complex consortia. Engineering synthetic microbial consortia can:

- Combine the strengths of different bacterial species.

- Enhance substrate utilization and electron transfer.

- Improve system resilience to environmental fluctuations.

For instance, pairing Geobacter sulfurreducens with Shewanella oneidensis has been shown to synergistically boost MFC output.

7. Integration with Artificial Intelligence (AI)

AI and machine learning are being applied to:

- Model and predict bacterial behavior under various conditions.

- Optimize MFC design parameters for maximum efficiency.

- Automate monitoring and control systems for real-time performance adjustments.

AI-driven optimization has reduced trial-and-error experimentation, accelerating MFC development.

Real-World Applications of Enhanced MFCs

Enhanced MFCs have the potential to revolutionize several industries:

1. Wastewater Treatment with Energy Recovery

Wastewater treatment is one of the most promising uses for MFCs. Enhanced MFCs provide a twofold advantage by treating organic pollutants and producing power at the same time. Streams of wastewater from industry, cities, and farms that are high in biodegradable substances provide excellent MFC substrates. Energy-neutral or energy-positive wastewater treatment plants are made possible by these systems, which use the microbial decomposition of organic materials to lower COD and generate bioelectricity.

2. Renewable Energy Production

As decentralized renewable energy sources for isolated or off-grid locations, enhanced MFCs are now under development. They are appropriate for rural electrification projects since they can run on a range of organic feedstocks, such as food waste and agricultural wastes. When combined with developments in electrode materials and biofilm engineering, MFCs can provide a sustainable energy source in areas without access to traditional power networks.

3. Biosensors for Environmental Monitoring

As biosensors for pollution detection, water quality monitoring, and soil health evaluation, MFCs are being utilized more and more. When pollutants like heavy metals or hazardous substances are present, the microbial activity inside MFCs reacts sensitively, changing the electrical output. These self-powered biosensors offer an economical and environmentally responsible way to monitor the environment in real time.

4. Powering IoT Devices and Microelectronics

MFCs are appropriate for small-scale applications, such as powering low-energy microelectronics and Internet of Things (IoT) devices, due to their steady yet low power output. Improved MFCs can supply sustainable power for wearable technology, sensors, and remote monitoring systems in the fields of environmental sciences, healthcare, and agriculture since they are made to run steadily and for extended periods of time.

5. Desalination Systems

MFCs are being integrated with desalination technologies to create microbial desalination cells (MDCs). These technologies lower the external energy requirements of desalination operations by using microbial activity to produce the energy needed for ion separation. MDCs are a significant advancement in energy-efficient, safe drinking water delivery in water-scarce areas.

6. Bioremediation of Contaminated Sites

The bioremediation of contaminated habitats, such as soil and water bodies tainted with hydrocarbons, pesticides, and heavy metals, can be aided by enhanced MFCs. In addition to decomposing these pollutants, the microbial activity in MFCs produces electrical signals that show the remediation’s progress, providing a dual purpose of monitoring and cleanup.

7. Educational and Research Tools

MFCs are becoming more and more popular as teaching aids at colleges and universities to instruct students on sustainability, microbiology, and renewable energy. Simplified MFC kits promote interest in green technology and multidisciplinary research while facilitating experiential learning.

Future Directions and Challenges

While innovative methods have significantly improved MFC efficiency, challenges remain:

- Scalability: Transitioning from lab-scale setups to industrial-scale applications.

- Cost-Effectiveness: Reducing the cost of advanced materials and processes.

- Long-Term Stability: Ensuring consistent performance over extended periods.

- Environmental Impact: Assessing the sustainability of synthetic mediators and nanomaterials.

Continued interdisciplinary collaboration among microbiologists, engineers, and material scientists will be essential to overcome these hurdles.

Wrapping Up

Using bacterial electron transport systems is a revolutionary way to increase MFC efficiency. Researchers are expanding the possibilities of bioelectrochemical systems by combining genetic engineering, nanotechnology, sophisticated materials, and AI-driven optimization. MFCs are positioned to be crucial to the global shift toward environmentally conscious practices and sustainable energy as these developments develop.

See Also: The Future of Microbial Fuel Cells: Harnessing Bacterial Electron Transport