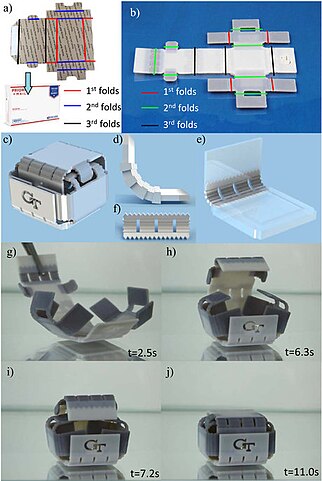

As of my last knowledge update in January 2022, four-dimensional (4D) printing is an emerging technology with the potential to revolutionize the manufacturing industry. 4D printing is an extension of 3D printing, where the fourth dimension refers to the transformation over time. It involves creating materials that can change their shape or properties over time when subjected to external stimuli, such as heat, moisture, or light. Here’s an exploration of the future of manufacturing through the lens of 4D printing:

1. Dynamic Structures:

- Self-Assembling Components: 4D printing enables the creation of structures and components that can self-assemble or change shape autonomously. This has applications in creating dynamic infrastructure or objects that adapt to their environment.

- Responsive Materials: Materials used in 4D printing can respond to external stimuli, allowing for the creation of structures that can expand, contract, or change their form based on specific conditions.

2. Biomedical Applications:

- Smart Implants: In the field of medicine, 4D printing holds promise for creating smart implants that can adapt to the patient’s body over time. This could include implants that change shape to fit the anatomy or release drugs based on the patient’s needs.

- Drug Delivery Systems: 4D printing can be used to manufacture drug delivery systems with responsive materials, allowing for controlled release of medication in response to physiological conditions.

3. Aerospace and Robotics:

- Adaptive Structures: In aerospace, 4D printing could lead to the development of adaptive structures for aircraft and spacecraft. These structures could change shape in response to different flight conditions, optimizing aerodynamics.

- Soft Robotics: The technology can be applied in the creation of soft robotics, where robots have flexible and adaptable components. This is particularly useful in applications where traditional rigid robots may not be suitable.

4. Construction and Infrastructure:

- Self-Assembling Buildings: 4D printing could revolutionize the construction industry by enabling the creation of self-assembling buildings or structures. Components could be printed and then transform on-site to form the final structure.

- Smart Infrastructure: Infrastructure components, such as bridges or pipelines, could be designed with 4D-printed materials that respond to environmental conditions, enhancing durability and resilience.

5. Consumer Products:

- Customizable Goods: 4D printing allows for the creation of consumer products that can adapt to user preferences or needs over time. This could include customizable clothing, footwear, or home goods that adjust based on user input or environmental factors.

- Sustainable Design: The ability to create products that can transform or adapt over time may contribute to more sustainable design practices, reducing the need for frequent replacements.

6. Supply Chain and Logistics:

- Smart Packaging: 4D printing could impact the packaging industry by enabling the creation of smart packaging materials that change shape or properties to better protect the contents or reduce waste.

- Responsive Logistics: Materials with 4D printing capabilities could be used in logistics to create packaging that adjusts to temperature changes during transportation or adapts to the size and shape of the packaged items.

7. Environmental Applications:

- Biodegradable Structures: 4D printing can be utilized to create biodegradable structures or products that change shape over time and eventually break down into environmentally friendly components.

- Adaptable Energy Systems: Components of energy systems, such as solar panels, could be designed with 4D-printed materials that optimize their orientation or shape based on sunlight conditions.

It’s important to note that as of my last update, 4D printing is still an evolving field, and practical applications are being researched and developed. The future of manufacturing, influenced by 4D printing, holds the potential for more adaptive, efficient, and sustainable production processes across various industries. Researchers and engineers continue to explore new materials and design possibilities, paving the way for innovative applications in the years to come.